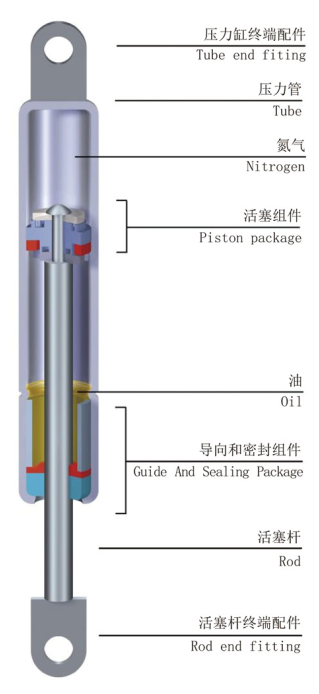

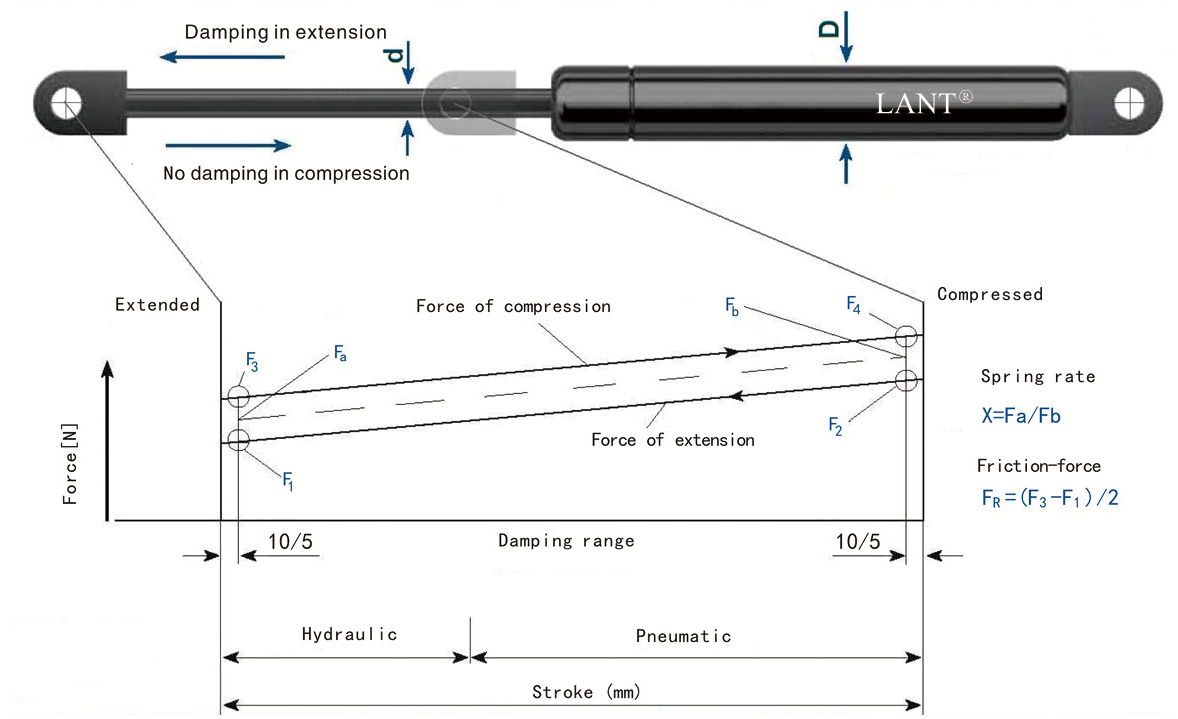

| Compressed gas spring: also known as support rod. It mainly plays a supporting role, there is no pause in the journey, and it can stay in the smallest and largest two positions of the journey. Its advantages are beautiful appearance, easy to use, small space and strong interchangeability. Now it is widely used in automobile, textile machinery, printing equipment, office equipment, construction machinery and other industries. The compressed gas spring has been developed into two types of atmospheric spring: constant damping gas spring and variable damping gas spring, the constant damping gas spring is damped through the piston damping hole; The variable damping gas spring is damped through the damping groove on the cylinder of the gas spring. There is also a gas spring with a safety protection device, when the gas spring fails during use, the safety protection device can effectively support the support to prevent the occurrence of safety accidents. The working principle of the gas spring is to use the inert gas as the elastic medium, and use the oil (such as transformer oil and turbine oil each 50%) to seal the lubrication and transfer the pressure of the elastic element referred to as the gas spring. It is actually a variant of the telescopic air spring, and it is also developed to further improve the elastic characteristics of the telescopic air spring. Therefore, it also has the general characteristics of air spring structure. The gas spring is generally composed of a cylinder, a piston (rod), a seal and an external connector. High-pressure nitrogen or inert gas and oil form a self-contained loop in the cylinder. The damping on the piston makes the rod-chamber and the rod-less chamber communicate, so that the pressure of the two chambers is equal. The elastic force is generated by the difference of the force area between the two cavities and the compressibility of the gas. The gas spring has light structure and large working stroke; The motion is smooth and can play the role of damping and buffering; It has a stable near-constant characteristic line; Easy to operate, safe and reliable. But the processing cost is high. |

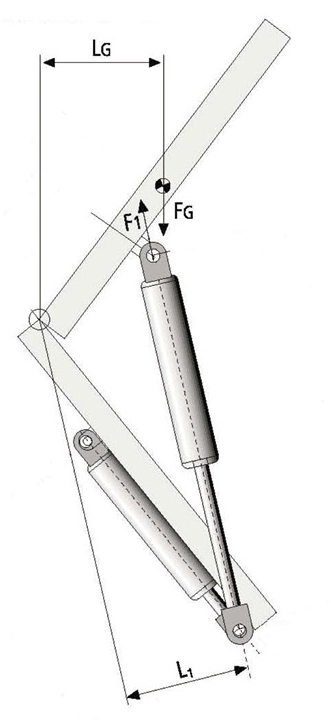

FN -- minimum extension force FG -- lifting gravity LG -- distance from center of gravity to center of rotation

L1 -- effective moment arm of aeroelastic extension n -- number of aeroelastic k -- safety factor :1.1--1.15

Gas spring force curve F1=(LG*FG/L1*n)*k

Application Areas