Cold-drawn tubes

Cold-drawn welded pipe is a kind of pipe made by using cold-drawing technology, cold-drawn pipe has the advantages of high strength, high precision, smooth surface, etc. Most of the precision steel pipes on the market now, the chemical composition mainly consists of there are carbon, silicon, manganese, sulfur, phosphorus, chromium several, has a stable trait, the advantages are very significant. From the use side, the advantages of precision steel pipe is also very significant, this type of pipe material in the automotive manufacturing industry, electric power petrochemical and aerospace ships, motorbikes, electric vehicles, bearings, pneumatic components, low and medium pressure boiler seamless steel pipe, etc., can also be applied to the steel sleeve, bearings, hydraulic, machining and other fields.

|  |

Advantages:

1. High strength: Cold-drawn welded pipe has a uniform composition and a dense internal structure, which gives it high strength, good gas tightness and corrosion resistance.

2. Economical: Compared to other types of pipes, the cost of cold-drawn welded pipes is relatively low, which makes it an economical choice.

3. Long service life: Cold drawn welded pipes are manufactured through a strict production process to ensure the quality and service life of the pipes. As a result, it is able to withstand high strength and pressure and has a long service life.

4. Excellent toughness: Cold-drawn welded pipe has excellent toughness and plasticity, and can withstand large stresses.

5. High forming efficiency: The speed and efficiency of manufacturing cold drawn welded pipes makes it a highly capable pipe material.

Disadvantages:

1. Defects: Cold drawn welded pipes may have some defects and faults in the manufacturing process, which may have an impact on the quality and service life of the pipe.

2. Not easy to repair: If there are problems with cold drawn welded pipes, it may be relatively difficult to repair them, requiring a large amount of human, material and financial resources.

3. There is the phenomenon of pipe motor: cold-drawn welded pipe in actual use may appear pipe motor phenomenon, which may affect the use of the pipe effect and life.

4. Need to pay attention to maintenance: cold-drawn welded pipe requires regular maintenance and care to ensure its long-term performance, if not properly maintained, may affect the use of the pipe.

In summary, cold-drawn welded pipe as a widely used pipeline material, has advantages and disadvantages, we should fully understand and understand these advantages and disadvantages, the strengths and weaknesses, reasonable selection and use of cold-drawn welded pipe, so as to better play its advantages and characteristics.

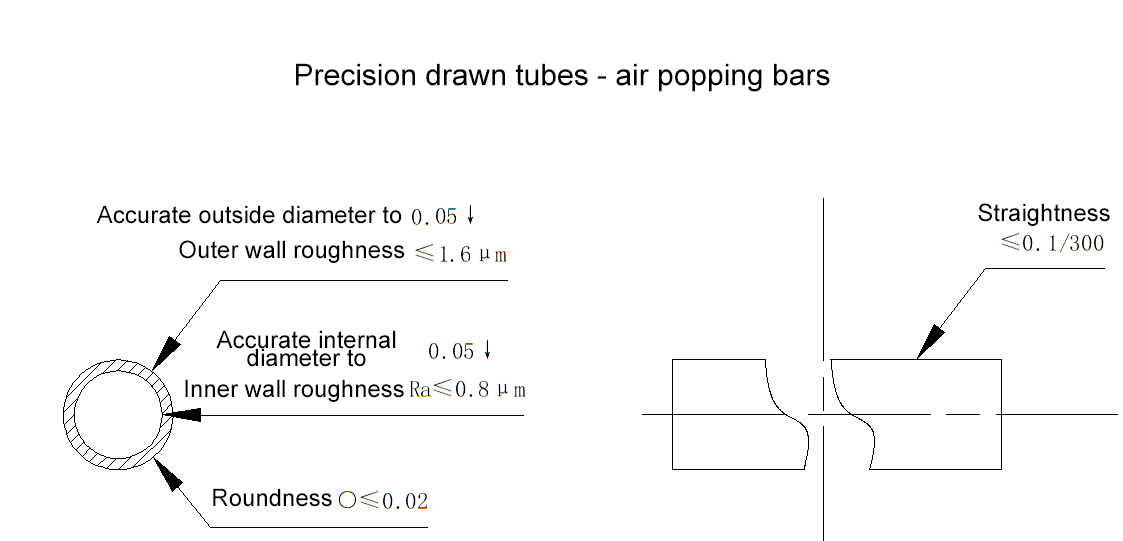

Execution standard:GB/T31315

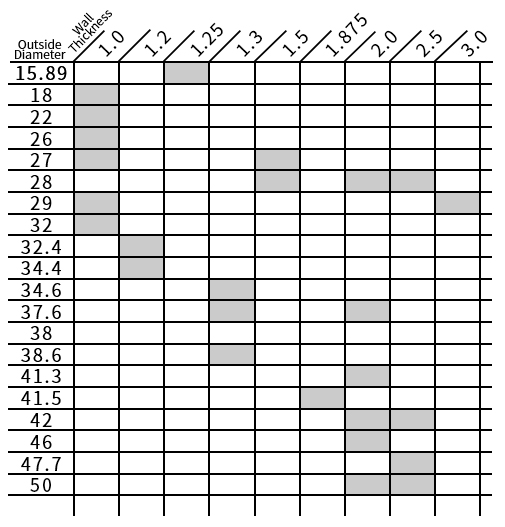

Production sizes:

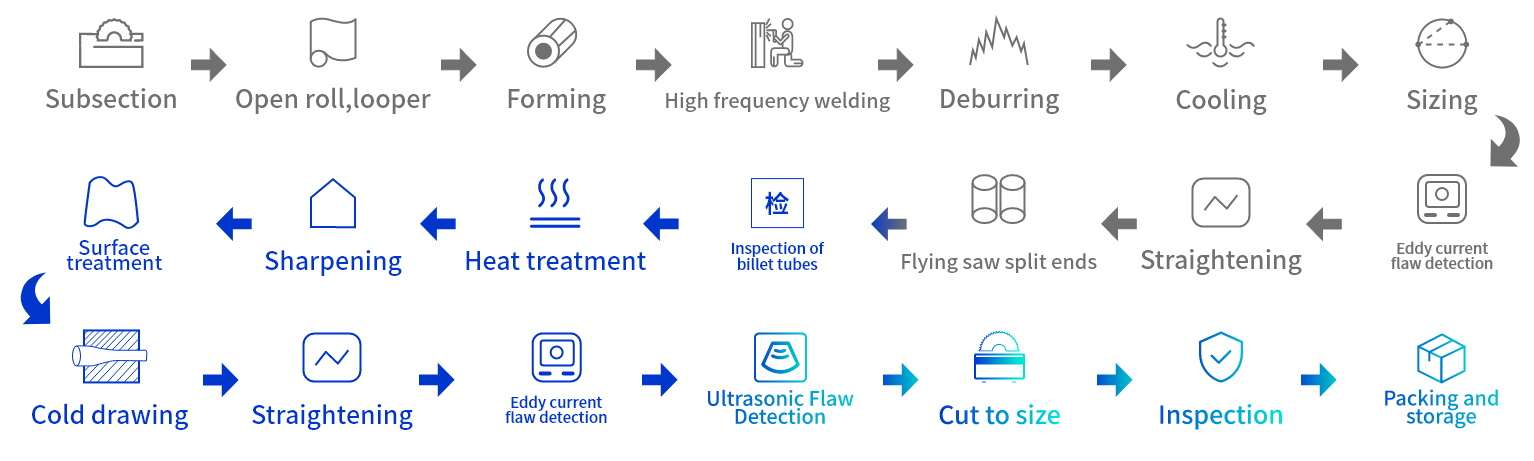

Process flow:

Product application areas:

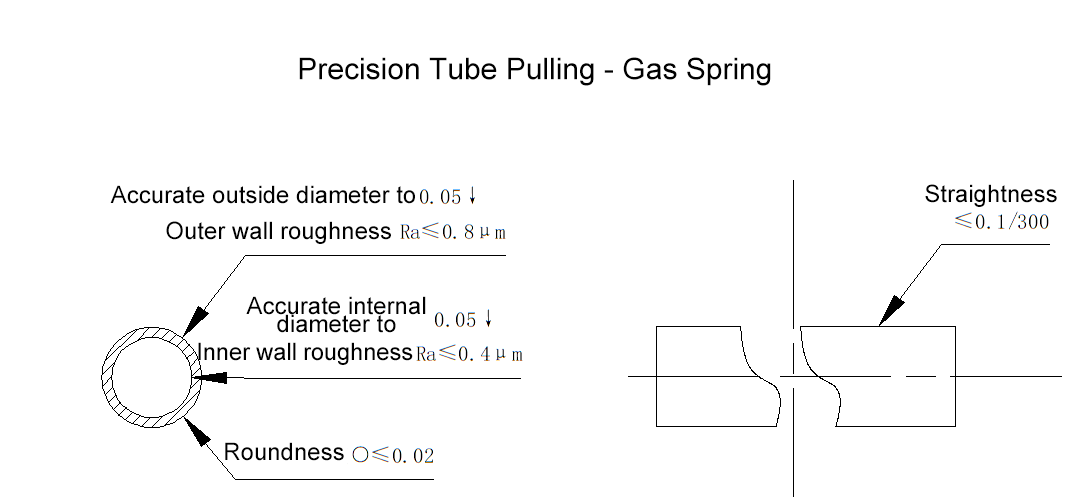

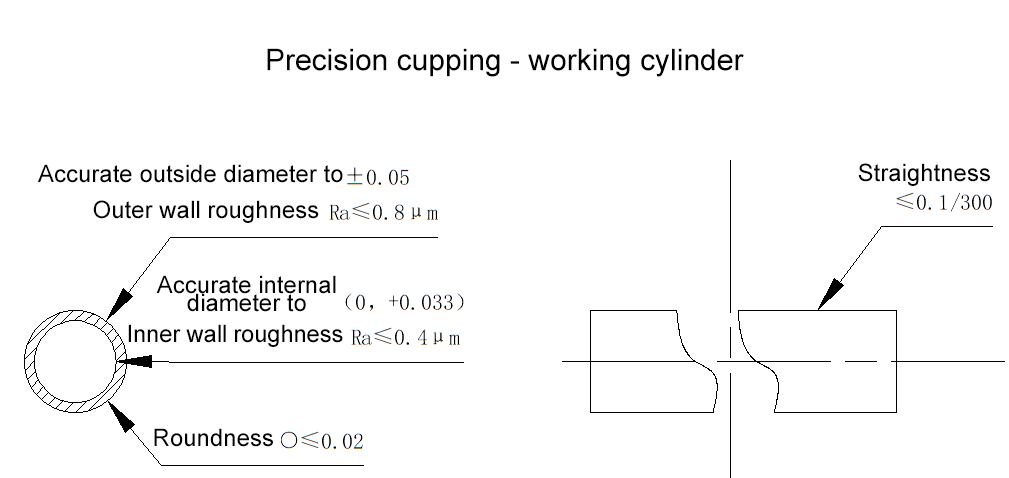

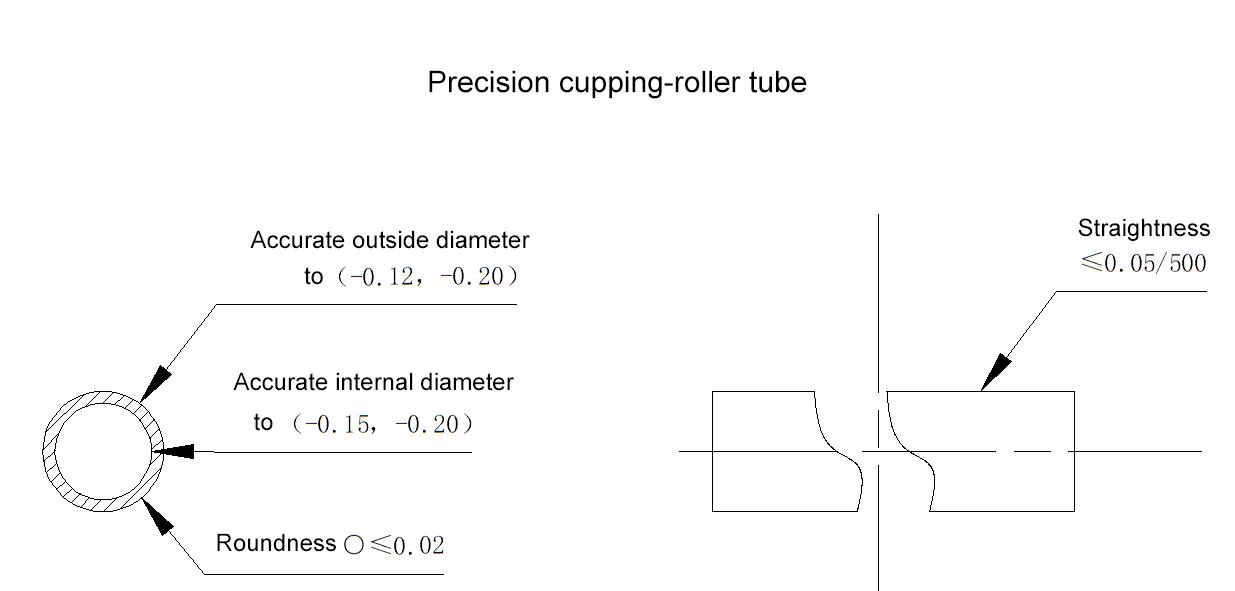

smart home (gas pressure bars, gas springs), automotive (work cylinders, trunk struts), fitness equipment (roller tubes)

Solution:

|  |

|  |